Products

-

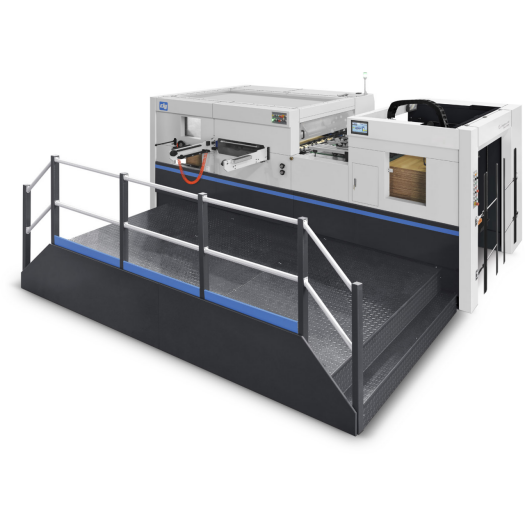

Automatic Type Corrugated Carton Box Making Machine

The fourth generation of MHC Series Automatic Manual Die Cutting Machine (Tiptronic Die Cutting Machine) based on the third generation of Semi-automatic Die Cutting Machine with Front Conveyor Delivery Mechanism, is equipped with automatic feeder, including both manual paper feeding and automatic feeder paper feeding function. On condition of flat corrugated paper, automatic feeder paper feeding is accepted with raising efficiency and reducing workforce.

-

3 5 7 Lawyer Automatic Flute Laminator Machine

1.Suitable for laminating of cardboard and corrugated cardboard in 150-600 g/m2 .

2.The vacuum suction-type feeding system can lead the paper accurately into the machine;cycle stacking planes in a state of non-stop the next batch of paper stack well, so that more efficient.

3.Using suction automatic feeding of bottom sheet, according to the main machine operating speed, continuous automatic tracking.

4.The machine operation is stable, surface paper with corrugated paper joint very accurate. The corrugated paper never pull ahead, surface paper’s location is easy adjust.

-

semi automatic flute laminator machine

Full computer touch screen control, panasonic PLC, invito servo drive motor. The main pressure is controlled by Taiwan delta frequency conversion, automatic glue-on control, glue-free alarm, counting, counting to alarm and other functions.

-

Thin Blade Slitter Scorer Machine

Change order fast, 3-8 seconds for changing order, the two machines can be achieved with no slow down immediately for a single.

Automatic tracking production line speed to ensure its synchronization with on-line production management system, and compatibility.

By the high-quality imports of industrial computers and high-performance programmable controller configuration, lower computer control system.

-

Single Facer Machine for Corrugated Production Line

*Single facer is design for producing single-face corrugated paper

-

Sheet Cutter Machine For Corrugated Production Line

1, Cutting length:500mm-9999mm.

2, Cutting precision:±1mm.

3, Uses the independent oil pump and the filter coordinates two groups of copper tubes to distribute in various gears position for the oil,the lubrication and cooling.

4, Helical knife structure,type sawtooth knife,decrease cutting obstruction,low noise.

5, Balance treatment:high quality alloy steel for blade shaft,which helps to keep it good stability.

-

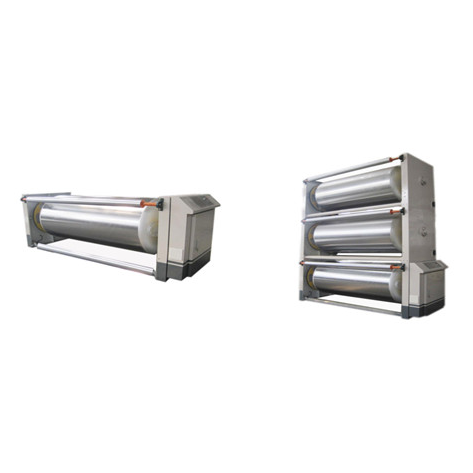

Pre-Heater for Corrugated Production Line

1, The preheater roller is under the stander of the 1st class(grade) pressure vessel of the national.

2, All the surfaces of every rollers have been grinded with high accuracy and chromed plated to less the resistance of paper preheating, long service of using life.

3, Electric to enlarge the preheating area, preheating area can be in 360° to adjust the preheating Area.

-

Hydraulic / Electric Mill Roll Stand For Corrugated Production Line

Working Pressure(mpa):16-18mpa,

lift hydraulic cylinder:Φ100×440mm,

Clamping hydraulic cylinder: Φ63×1300mm

Power Motor for Hydraulic Station:3KW –380V — 50Hz

Magnetic Valve Voltage:380V 50HZ

-

Double Facer MachineDouble Baker

*Corrugated paper enter into the double facer hot parts with heating and molding after pasted glue, and become board after cooling

-

5 Ply Corrugated Cardboard Production Line

Main shaft diameter is 242mm,doublecurve heavy rocker arm, tooth clip,mulitpoint brake,hydraulic lift,left and right translation.

Guide rail length is 6000 mm, the car uses 10 mm plate welding

-

3 Ply Corrugated Cardboard Production Line

–Toothed chuck,manual discbrakes,pneumatic mechanically actuated lift,panning left and right on the middle

–Guide rail length is 4500 mm, the trolley adopt 10 mm plate welding

-

7 Ply Corrugated Cardboard Production Line

Main shaft diameter is 242mm,doublecurve heavy rocker arm, tooth clip,mulitpoint brake, hydraulic lift, left and right translation.

Guide rail length is 6000 mm, the car uses 10 mm plate welding